Boom Supersonic is an aerospace startup trying to build a supersonic airliner. The company has garnered a lot of attention recently after successfully flying their XB-1 test aircraft faster than the speed of sound, the first privately-developed aircraft to do so. Boom’s supersonic airliner, the Overture, is projected to carry 64–80 passengers (depending on how it’s configured), and is slated to begin commercial flights in 2029.

Boom has gotten a lot of attention after successfully breaking the sound barrier, but most of the discussion around the company that I’m seeing isn’t really grappling with the challenges the company is facing. The XB-1 supersonic flight is impressive, but to me there are basically four major points to consider when evaluating Boom’s prospects:

How hard is it to develop a commercial aircraft?

How hard is it to develop a commercial jet engine? (Boom is designing its engine in-house, rather than one provided by a major engine manufacturer like Rolls-Royce or Pratt & Whitney.)

How likely is it that Boom can do both at the same time?

If it does, will the economics of its supersonic transport business work?

Almost all the discussion I’ve seen has centered on #4: whether a supersonic airliner business can be viable. There are lots of comparisons to Concorde, the British-French supersonic airliner that failed in part due to high ticket prices and limited numbers of routes. I see plenty of speculation about how big the supersonic airliner market is, and whether Boom can overcome Concorde’s failures.

But in my mind the biggest questions are #1–3. Before Boom deals with the market risk of building a viable business, it needs to work through the technical risk of building the actual airliner.1 Building commercial aircraft and jet engines are some of the most difficult things that civilization accomplishes, and I expect trying to do both at the same time will be very difficult indeed. How well Boom executes its development program will have a huge impact on whether or not it has a viable business: the cheaper development is, and the more successful Boom is at achieving low manufacturing cost and high fuel efficiency, the easier it becomes to operate profitably.

We also don’t yet have much evidence as to Boom’s progress in building its airliner. People are treating the XB-1 flight as a major milestone and a strong indicator that they’ll be successful. To me, flying the XB-1 — while an impressive achievement — does not tell us all that much about how well the company will execute on the airliner and the engine that powers it.

Building commercial aircraft is hard

I’ve previously written about the trials and tribulations of building a new commercial aircraft. The long and short of it is that bringing a new commercial aircraft to market is extremely difficult and expensive. New aircraft development cost billions or tens of billions of dollars, and final costs are often multiple times initial estimates.

Boeing spent an estimated $14 and $15 billion to develop the 777 and the 787, respectively, two to three times as much as initial cost estimates. Airbus spent a similar amount on its A350, and more than twice as much to develop the A380. Bombardier spent nearly $6 billion in a failed attempt to develop a competitor to Boeing’s 737, and Mitsubishi spent nearly $10 billion in a failed attempt to build a regional jet.

And while it's definitely gotten more expensive over time to develop a new commercial aircraft, it’s always been an expensive and risky endeavor. Boeing spent nearly $200 million (roughly $2 billion in 2025 dollars) to develop its first jetliner in the 1950s, the 707: substantially more than the company was worth at the time. Boeing bet the company again on the 747 in the 1960s, spending an estimated $2 billion (~$17 billion in 2025 dollars) on the program. And Boeing wasn’t alone. By the late 1960s, aircraft manufacturers were regularly spending $1 billion or more on new aircraft programs, and the high costs and risks drove many companies to exit the business. For instance, Lockheed gave up on the commercial aircraft business after losing an estimated $2.5 billion on the Lockheed Tristar.

The supersonic Concorde, the obvious comparison to Boom, had a similar trajectory. Its ultimate development costs were well over $2 billion (~$19 billion in 2025 dollars), vastly more than initial estimates, and the program never came close to making a return on its investment.

These high costs and risks are why firms like Boeing and Airbus will often move heaven and earth to avoid designing a new clean sheet aircraft, and why Boeing has kept on rolling out modified versions of the 737 for almost 60 years.

Thus, when developing a new commercial aircraft, even well-established firms with decades of aerospace experience under their belt regularly fail: projects will often never get completed at all (like the Spacejet), or they fail to recoup their development costs (the Concorde, the Tristar, the A380).

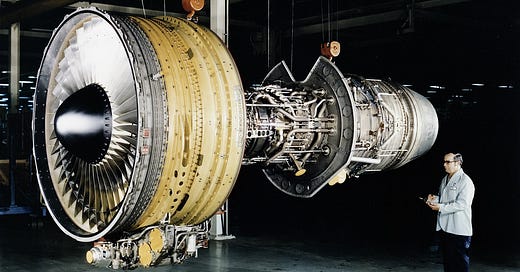

Building a commercial jet engine is hard

The story of commercial jet engines is broadly similar to that of commercial aircraft: developing a new one is a risky, multi-billion dollar endeavor, and firms generally try to minimize that risk by extending existing models rather than starting from scratch with clean sheet designs. Often this means basing a commercial engine on an already-existing military engine, where the government has picked up the development tab.

Pratt & Whitney spent an estimated $10 billion to develop its geared turbofan. CFM likely spent billions to develop its LEAP line of engines. As with aircraft, new engine development has always been expensive: as early as the 1950s new jet engine projects cost billions of 2025 dollars to develop. And like with commercial aircraft, failure is a familiar companion to these projects, even at well-established aerospace companies. Cost overruns on the RB211 drove Rolls-Royce into bankruptcy, Pratt and Whitney spent billions dealing with manufacturing issues on the geared turbofan, and difficulties building a successful new engine had driven many early jet engine manufacturers from the field by the 1960s.

It’s important to note that early on, Boom planned on having an existing major jet engine manufacturer build its engines. Boom spent several years working with Rolls-Royce on an engine design for their airliner, but Rolls-Royce later pulled out of their partnership, and neither GE Aerospace or Pratt & Whitney, the other two major manufacturers of commercial engines, were apparently interested in the project. Boom has thus cobbled together a team to get its engines built. Boom itself is leading the engine design effort, in partnership with Florida Turbine Technologies, a subsidiary of Kratos Defense. GE subsidiary Colibrium Additive will consult on additive manufacturing techniques, and StandardAero will assemble and maintain the engines.

Historically, aircraft manufacturers haven’t also tried to design and build their own engines (though new engine development does often take place concurrently with new aircraft development). Boeing, Airbus, Embraer, and COMAC all use engines built by Rolls-Royce, Pratt & Whitney, or GE/CFM. The Concorde used a redesigned Rolls-Royce Olympus engine developed for the UK’s TSR-2 bomber program.

What are Boom’s odds of successfully doing both?

Given this historical background, my basic model is that building commercial jet engines and commercial aircraft are two of the most difficult things for an organization to do. Projects often fail or go massively over budget, even at established aerospace companies with decades of experience trying to do just one of these. Most startups fail, and I’d expect a startup trying to do two of the hardest things at the same time to have an even lower probability of success.

But this is an extreme outside view, that doesn’t take into account any actual information about Boom. We can modify this basic model based on what we know about Boom’s technology choices and the history of the company.

First, let’s consider the technical aspects. New aircraft and jet engine programs are so expensive and difficult in part because they’re typically pushing performance boundaries forward: aircraft that are lighter and have better aerodynamics, engines that run hotter and at higher compression, and so on. If you don’t need to push technical boundaries, then your technical risk and your development costs should be lower.

This is the path Boom says it's taking, minimizing risk by repackaging already existing technology. Via Freethink:

“We didn’t need to invent anything,” said [Boom founder Blake] Scholl. “What we’re doing is basically taking the same 20-year-old technology that was on the Boeing 787 and just changing the design of the airplane.”

“We took a 787, we shrank it down, we stretched it out, made it long and skinny, and then we put twice as many engines so it would go twice as fast,” he continued. “That’s it. It’s an evolved design, but it’s not made out of unobtainium.”

I understand why Boom would make this claim (since if true it means much lower technical risk), but I’m not sure how valid it is. For one, while not bleeding edge, Boom seems like it’ll be operating close to the current performance frontier, which I still expect to be difficult for a new company. For instance, turbine inlet temperature (TIT) is one performance metric of jet engines: the hotter the gas going into the turbine, the more efficient the engine runs, and inlet temperatures have gradually climbed over time. Boom is targeting an inlet temperature of around 2,800 degrees Fahrenheit.2 This is indeed behind state of the art (which seems to be closer to 3,150 degrees), but not that far behind — it’s only slightly cooler than the inlet temperature on CFM’s LEAP, which entered service in 2016. Boom is also apparently using 3D-printed parts in its engine, another relatively recent engine technology development.

Similarly, Boom is targeting a time-on-wing (that is, time between major overhauls) of 5,000 hours for its engine. This is indeed substantially less than what a tested, well-vetted engine design can achieve. The CFM56, regarded as one of the most reliable engines ever built, can apparently achieve 25,000 hours of on-wing time. But for a new engine, I still expect 5,000 hours to be difficult to do: that seems to be roughly what the CFM LEAP is achieving in at least some cases. And achieving this will be more difficult for Boom, because supersonic engines are pushed harder than subsonic ones.

Related to the last point, Boom may be using already existing technology, but it’s using it in a fundamentally new domain of supersonic flight. Taking existing aerospace technology like, say, the carbon fiber structure of the 787, and adapting it to much higher speeds is not something I expect to be straightforward, and is the exact sort of new domain exploration that tends to be expensive and difficult.

Boom will also need to use certain technologies that aren’t required on a conventional, subsonic airliner. Compared to subsonic engines, supersonic engines require a more complex intake system to slow down the air before it reaches the engine, as well as a more complex nozzle system for the air exiting the engine. These aren’t things Boom can just emulate from the 787. The intake and nozzle system on Concorde were among the most difficult parts of the project. Via Concorde: New Shape in the Sky:

Astonishingly, such are the pressures and forces throughout the powerplant, the two-most important components are thus seen to be the air intake and the final nozzle. Together they exert virtually the whole of the next thrust in cruising flight; clearly their efficiency is of paramount importance in determining the performance of the powerplant. Juggling with the temperatures, pressures and air speeds in the intake; the temperatures, pressures and compressor speeds in the engine; and the pressures and temperatures in the nozzle, so that they are all in tune — and controlling the conditions so that they remain in tune throughout the widely varying flight conditions — posed an immense development task.

So overall, I expect the technical risk Boom faces is at least similar, and possibly much greater, than a typical commercial aircraft development project. I also expect that the larger flight envelope of a supersonic airliner (the range of speeds and air conditions it will encounter) will require more testing (and thus more expense) than a conventional, subsonic airliner. (Concorde certainly did.)

One might expect that the successful supersonic flights of Boom’s XB-1 demonstrator means that this technical risk is reduced — Boom has now shown it can build and fly a supersonic jet, they just need to scale it up. But while flying the XB-1 is extremely impressive, I don’t think it tells us all that much about whether Boom can build a supersonic airliner.

For one, while XB-1 is called a “technology demonstrator,” there’s not all that much overlap in the design of the XB-1 and the design of the Overture. The XB-1 uses a different wing shape, a different engine arrangement (three on the XB-1 vs. four on the Overture), and an off-the-shelf J85 jet engine, rather than one Boom is designing. There’s some overlap — the XB-1 gives Boom experience building carbon fiber airframes, and allowed it to test some cockpit systems — but the Overture and the XB-1 are fundamentally different aircraft. While the XB-1 was originally planned to be a scaled-down version of the Overture, the designs diverged, and Boom has now stated that the primary purpose of XB-1 is mostly to show that Boom can build a supersonic aircraft. Given the immense amount of attention the XB-1 flight has gotten, it’s hard to argue that this strategy wasn’t successful, but I’m not sure it does much to de-risk the technical aspects of the airliner.

And as with jet engines, the hard part of building a commercial aircraft isn’t necessarily building a plane that flies. It’s building one that meets its various performance requirements, including efficiency, reliability, and safety. Boom has shown it can do the former, but I’m not sure this says all that much about whether it can do the latter. XB-1 only flew a handful of times before being retired, nowhere near the extensive testing that a commercial aircraft requires. The Boeing 787, for instance, underwent 5,000 hours of flight testing.

The relatively limited number of flights the XB-1 took before being retired also seems unusual to me. I’m not sure why, after spending hundreds of millions of dollars on the aircraft, there’s really nothing more for Boom to do with it: no system that can use it as a test bed, no high-speed phenomena they want to better understand. (By comparison, an early test aircraft for the Concorde, the BAC-221, flew hundreds of times over a period of years before being retired.) Similarly, it seems notable that the XB-1 never approached the design speed of the Overture. While the Overture is aiming for Mach 1.7, the XB-1 only reached Mach 1.1. And apparently the XB-1 was originally slated to reach a speed of Mach 2.2 (the design speed of the Overture at the time.)

More generally, we just don’t yet have all that much information about Boom’s progress on the actual airliner. The company aims to complete the Symphony engine core (compressor, combustor, and turbine) by the end of this year, which will give us more information about their progress. (Though I would caution not to over-index on this future announcement: I think it’s likely Boom will be able to produce a working engine, but one that meets its performance requirements will be substantially harder.)

When trying to weigh Boom’s chances, we can also consider organizational factors. Boom appears to have hired a lot of aerospace talent. Multiple team members have won American Institute of Aeronautics and Astronautics (AIAA) awards, and the company is staffed by folks who have formerly worked at places like Gulfstream, Boeing, ULA, and Scaled Composites. On the engine, Boom has been able to leverage a former Pratt & Whitney team who designed the F135 engine for the F35 fighter (per Boom, the team left Pratt & Whitney and formed Florida Turbine Technologies (FTT) when Pratt & Whitney closed a Florida office.) These all seem like positive signals to me, particularly the former F135 team. FTT mostly seems to build very small jet engines for drones and missiles, so having some folks who previously designed a large, manned aircraft engine seems important.

I still think there’s a good possibility of development difficulties, though. The F135 was designed close to 20 years ago and FTT was founded more than 25 years ago, so I expect there to be some amount of organizational forgetting if they haven’t designed a large aircraft engine since then. I also expect a commercial engine to have a different (though overlapping) set of development difficulties than a military engine.

Boom also claims that designing its own engine in-house will ultimately be a benefit, because it will allow for such close coordination and optimization between the engine and airframe design. This doesn’t seem totally implausible to me, but it obviously trades off against the knowledge and experience that an existing commercial engine manufacturer has.

We can also consider the overall arc of the company. Boom has gone from basically nothing to flying a supersonic aircraft, which as I’ve noted is an impressive achievement. But it’s not an achievement that has come easily. The company was founded in 2014, so it took Boom over 10 years to go supersonic with the XB-1. And it’s had to repeatedly push back its estimated completion dates. Boom originally planned to fly the XB-1 in 2017, and to enter commercial supersonic service in 2023. Instead, the XB-1 didn’t roll out until 2020, and didn’t fly until 2024. Boom is currently aiming for 2029 for entry into service, though I would be surprised if it hits this date. Along the way, Boom has burned through around $600 million worth of investment and $250 million of additional funding, and it was only a $100 million “down round” (investment at a lower valuation) last fall, accompanied by a large layoff, that allowed Boom to stay afloat.3 (Founder Blake Scholl originally claimed that $33 million would be sufficient to get the XB-1 “through flight tests.”)

For another perspective on the operations of the company, we can look at Glassdoor reviews left by Boom employees. The current rating of the company is 2.5 (not particularly great), and the average rating has trended downward over time.

Many of the bad reviews are sort of standard startup stuff (lots of pressure, long hours, lack of structure), but among them are more pointed critiques of the company’s operations. A sample:

“Poor management, control freak CEO with no relevant technical background, infighting/politics, many under-experienced engineers in key roles leading to quality/safety issues, marketing lies.”

“Boom has blown through funding that was intended for goals and benchmarks that are long overdue, and are not even close to completion. Two of three founders have left the company and turnover in management roles is multiples above industry standards.”

“Company is vaporware and bound to fail.”

(I was only able to find one founder that left the company, Josh Krall.)

Similarly, on LinkedIn, Boom’s former Chief Aerodynamicist, Steven Ogg, was highly critical of the company:

Founder Blake Scholl has also noted that Boom almost failed “many times” over its history.

I’d caution against putting too much weight these sorts of negative employee reports. Many successful startups will have early growing pains and (probably) lots of similar-sounding employee complaints. And we can ascribe some negative sentiment to former employees unhappy about losing their jobs. But I do think they add color to the picture. Overall my impression of Boom is a company that has struggled a lot (and spent a lot) to get where it is. This is understandable (building a supersonic aircraft is hard!), but it’s important to note that these struggles have taken place before Boom has gotten to the hardest part: building the airliner, the engine, and raising the billions of dollars required.

The business case for supersonic travel

I’m not going to spend too much time on the business case for supersonic travel, but I will note a few points. The obvious point of comparison here is Concorde, which failed due to a combination of high costs and limited demand. There just weren’t enough routes where a supersonic airliner was allowed to fly that people were willing to pay the high prices for.4 Only a tiny number of Concordes ended up being sold, and none of them could operate profitably.

The counterpoint is that the world is much richer today, many more people fly, and there are thus a lot more viable supersonic routes. By taking advantage of 50 years of progress in aircraft technology, a modern supersonic airliner should be more efficient, and be able to fly much more cheaply than Concorde did. This is all true (Leeham News notes some of the things that are much easier to achieve in supersonic flight today than they were in the Concorde era), though it’s not clear to me how low we can expect Boom’s operational costs to be.

We can also point to the number of orders that Boom has accumulated (130 at the time of this writing), as evidence for the demand for supersonic flight. This is also true, though once again we should be careful not to overindex on this. These are conditional orders, and may represent very small financial commitments. Concorde also had a large order book early in its development, nearly all of which were later cancelled. On the other hand, Japan Airlines’ $10 million investment in Boom should be regarded as a strong positive signal.

I’m not going to speculate about the number of viable supersonic routes (or Boomless cruise routes), but I will note that the economics of the business heavily depend on how well Boom executes on their development program. If Boom’s development costs are too high, or they can’t get their aircraft weight, fuel efficiency, or maintenance costs low enough, that will obviously have a major impact on how much airlines need to charge per ticket and how viable the business is. Boom has estimated they need $6–8 billion to complete development, and I suspect this is an underestimate: industry analysts have pegged the likely costs as closer to $10 billion. And it’s easy to imagine costs going much higher: it’s not uncommon for new aircraft programs to be 200% over budget or more, and Boom has already significantly underestimated the development costs of the XB-1.

Moreover, historically commercial aircraft haven’t been particularly good investments. In his 1982 book about the commercial aircraft industry, John Newhouse notes that only two or three of the 22 commercial jetliners that had then been developed were believed to have made any money. For all Boeing’s success as an aircraft manufacturer prior to its ill-fated merger with McDonnell-Douglass, it only managed to eke out something like a 5% profit between 1970 and 2010. For a company like Boom that needs to raise billions of dollars before it even has a product it can offer, these seem like tough numbers.

Is Boom the SpaceX of supersonic flight?

SpaceX obviously paved the way for Boom. SpaceX showed that existing aerospace companies were often incredibly inefficient, and that it was possible for someone with a startup mentality and no aerospace background to come in and run circles around the existing players. You could have written a very similar essay to this one 20 years ago when SpaceX was trying to get off the ground — “rocket manufacturing is so hard and so risky, it takes huge amounts of money, SpaceX has struggled a lot, there’s no reason to expect these upstarts to succeed” — and you would have wound up being wildly wrong. And it’s not as if current aircraft manufacturers have been paragons of competence: nobody looks at present-day Boeing and sees a company at the top of its game. It’s not hard to imagine a nimble startup coming in and executing an aircraft development program far more competently.

I don’t think this analogy is valueless, but it’s easy to take the comparison too far. For one, I suspect there was a lot more “slack” in the rocket business than in the commercial aircraft and jet engine business. Aircraft and engine manufacturers are selling to airlines in an extremely competitive market, and are under constant pressure to drive down their various costs. Note that while launch costs didn’t fall at all between the Saturn V in the 1960s and the rise of SpaceX, commercial aircraft got much cheaper to operate over the same period.

Another reason this comparison is tricky is that if you’re relying on a company being as good as SpaceX, that seems like a situation where your odds are low. Most companies will not be as good as SpaceX! I’m not an aerospace expert, but reaching orbit with a rocket and achieving supersonic flight seem like they might be roughly comparable in difficulty. They were first achieved at broadly similar times (1947 vs. 1957),5 and there seem to be comparable numbers of orbital launch systems as there are supersonic aircraft. If we assume for the sake of argument that Boom circa 2025 and SpaceX circa 2008 have achieved similarly difficult aerospace achievements, it’s notable that Boom needed much more time (10 years vs 6), and needed much more money: Boom’s total funding is on the order of $850-$950 million, SpaceX’s was around $200 million (~$295 million in 2025 dollars).67 If you think putting a rocket into orbit is the much harder achievement (both Claude and o1 do), then that only further emphasizes the point.

(I would be very interested to hear from aerospace experts whether they think launching a rocket into orbit or achieving turbine-powered manned supersonic flight is more difficult.)

And Boom is much further from having a product than SpaceX was at a similar point in its history. SpaceX’s first successful orbital launch with the Falcon 1 was in 2008, which enabled the company to secure $1.6 billion in NASA funding for commercial resupply to the ISS. Its first successful Falcon 9 launch, the rocket that became the backbone of its business, was just two years later in 2010. And the Falcon 9 used the Merlin engines that had powered the Falcon 1.

Boom, on the other hand, appears to have much further to go. It doesn’t yet have its own engine, it hasn’t (as of February) completed the design of its airliner, it hasn’t yet reached its design speed of Mach 1.7, and it hasn’t received any large injections of funding following the flight (though it could of course get some, and I expect it’s working on this). I don’t expect Overture to first fly in 2027, and I don’t expect it to start commercial service in 2029 (the 2029 date was originally based on having a demonstrator build of the aircraft by 2022 and initial roll-out by 2025, so it seems like that date should push by at least several years.) Overall, I see a longer and more difficult path ahead of Boom than was ahead of SpaceX did at a similar point in its history.

One final Concorde comparison is appropriate. The “technology demonstrator” for the Concorde, the BAC-211, first flew in 1964. But the Concorde itself didn’t fly until 1969, five years later. And it didn’t enter commercial service 1976, almost 12 years after the testbed first flew.

I hope Boom is successful, because it would be great to have supersonic airliners (and to have another US company capable of building commercial aircraft). But to me it seems the odds are steep, and they have a very long way to go.

Though obviously an analysis of the market is key for deciding whether it’s worth trying to solve the technical problems.

It’s possible Boom is referring to a slightly different point with regards to TIT, which would put it even further behind state of the art.

There’s some slight inconsistency in the funding numbers I’ve found. Some say $600 million of investment prior to the $100 million round last fall, and some say $600 million after that investment.

The one “profitable” route, New York to London, was ultimately profitable enough for airlines to recoup operational costs, but not the upfront costs of the actual airliner.

If you instead consider turbine-powered supersonic flight by an aircraft that has to take off and land, that wasn’t achieved until 1953 with the F-102.

By the successful Falcon 1 launch, SpaceX had gotten $100 million from Elon Musk, $20 million from Founders Fund, a portion of the NASA COTS contract money (probably around $40 million), and some payments from DARPA and early customers.

The XB-1 isn’t the only thing Boom has spent its funding on. It’s also finishing design of Overture, building a factory for it, and developing its jet engine. But Falcon 1 also wasn’t the only thing SpaceX was working on at the time: it was also developing Falcon 9 and the Dragon Capsule.

I think it is important to note that the real competitor to supersonic planes is actually WiFi on commercial aircraft. Unlike the Concorde era, you’re no longer disconnected while in the air.

One other point why the SpaceX comparison is not valid: a major reason for the slack in space travel is the rockets' non-reusability. SpaceX fixed that; in fact the difference between their external prices and their internal cost is probably rather large given how many "unpaid" Starlink launches they do.

Airline travel has the opposite problem, in that base prices are much too low; large airliners requires a dose of artificial scarity and a mix of seat prices to be even moderately profitable. (Or, if you're a cheapskate airline, absurd surcharges for literally everything.)

Getting a supersonic plane to the point where it's profitable, considering its high fuel consumption and running cost, esp. per passenger, will be extremely difficult, if not impossible. Personally I'd bet on the latter.